Actuators are vital components in various systems, playing a key role in converting energy into mechanical motion. They are used across a wide range of industries, from industrial automation to robotics, energy production, and beyond. In this article, we will explore AV actuators, compact electric actuators, AVA smart actuators, and valve actuators, discussing their functionalities, advantages, and applications. By understanding these actuator types, businesses and engineers can make informed decisions when selecting the right actuator for their needs.

What Are Actuators?

An actuator is a device that converts various forms of energy (electric, pneumatic, hydraulic) into mechanical motion, either linear or rotary. They are essential in controlling systems and machinery, providing the necessary motion to execute tasks like opening valves, moving robotic arms, or adjusting the flow in pipelines. Actuators are categorized based on their energy source, application, and form factor. In this article, we focus on four specific types: AV actuators, compact electric actuators, AVA Smart Actuators, and valve actuators.

AV Actuators: Precision and Control

AV actuators are highly precise and reliable devices used primarily in industrial applications that require accurate control of airflow, fluid flow, or pressure. These actuators are widely employed in HVAC systems, chemical plants, pharmaceutical manufacturing, and other industries where precision is critical.

The main advantage of AV actuators is their ability to operate seamlessly with control systems, allowing for efficient automation. They are used to control dampers, valves, and other systems with high accuracy. This capability is crucial for industries that rely on maintaining strict conditions, such as cleanrooms in pharmaceuticals or automated fluid control in chemical processing. The precision of AV actuators ensures that systems remain efficient and stable, reducing energy consumption and operational costs.

Compact Electric Actuators: Small Yet Powerful

Compact electric actuators are designed to provide high levels of performance in a small form factor. These actuators are perfect for applications where space is limited, but the need for accurate and reliable motion control remains high. Compact electric actuators convert electrical energy into mechanical motion, typically in either linear or rotary form, and are widely used in industries like robotics, medical devices, automotive systems, and small automation applications.

One of the key benefits of compact electric actuators is their ability to fit into tight spaces without sacrificing performance. Their small size makes them ideal for applications such as robotic arms, where a larger actuator might not be feasible. Despite their compact size, these actuators provide reliable and precise control, often equipped with sensors to enable feedback and enhance their functionality.

Additionally, compact electric actuators are easy to integrate into systems that require high efficiency and minimal footprint. They can be used in environments where space is at a premium, such as in aerospace, electronics, and even medical applications, where actuators might be required to control devices in small, confined spaces.

AVA Smart Actuators: The Future of Intelligent Automation

In the world of automation, AVA smart actuators represent a significant advancement. These actuators are equipped with smart features, such as sensors, IoT connectivity, and real-time data monitoring, which make them highly efficient and adaptable to dynamic environments. AVA smart actuators are commonly used in applications that demand intelligent control, such as HVAC systems, energy management systems, and industrial automation.

The most significant advantage of AVA smart actuators is their ability to communicate with other devices in an interconnected system. This feature allows for the automation of complex tasks, reducing the need for human intervention. In industrial settings, AVA smart actuators can automatically adjust based on feedback from sensors, ensuring that the system operates efficiently and effectively without manual input.

Furthermore, AVA smart actuators can predict potential failures and perform self-diagnostics, allowing for predictive maintenance. This capability reduces downtime by addressing issues before they cause significant disruptions. With the integration of IoT (Internet of Things) technology, AVA smart actuators can be remotely monitored and controlled, offering increased convenience and operational flexibility.

Valve Actuators: Precision Flow Control

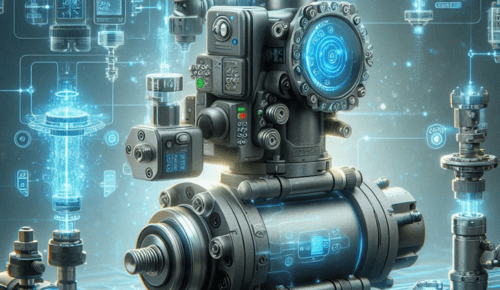

Valve actuators are designed specifically for controlling the movement of valves within a system, allowing for the regulation of fluids, gases, or steam. They are commonly used in industries such as oil and gas, water treatment, power generation, and chemical processing, where precise control of flow is essential.

The function of a valve actuator is simple but crucial: it converts energy into mechanical motion that opens or closes a valve to regulate the flow of material through a pipeline or system. There are various types of valve actuators, including electric, pneumatic, and hydraulic, each suited for different applications based on their force requirements, speed, and the type of system they are used in.

Electric valve actuators are ideal for systems that require precise and automated control, as they can be easily integrated into control systems. Pneumatic and hydraulic actuators, on the other hand, are preferred for applications that require high forces or rapid actuation. In all cases, valve actuators ensure the safe and efficient operation of fluid systems, protecting infrastructure and improving system performance.

Applications of Actuators Across Industries

The four actuator types discussed – AV actuators, compact electric actuators, AVA smart actuators, and valve actuators – are used in diverse industries for various applications:

- Industrial Automation: Actuators play a key role in manufacturing lines, controlling machinery, and ensuring precision during assembly and packaging.

- HVAC Systems: AV actuators and AVA smart actuators control air dampers and valves to regulate airflow and temperature.

- Robotics: Compact electric actuators are widely used in robotics for controlling joints, arms, and other components that require high precision.

- Oil & Gas: Valve actuators are essential in controlling the flow of liquids and gases in pipelines, refineries, and storage tanks.

- Energy and Power: Valve actuators regulate the flow of steam and gas in power plants, ensuring efficient energy production.

Conclusion

Actuators are the backbone of modern automation and control systems, ensuring that mechanical systems operate smoothly and efficiently. Whether you’re using AV actuators for precision control, compact electric actuators for space-saving designs, AVA smart actuators for intelligent automation, or valve actuators for fluid control, each type of actuator serves a critical role in different applications. As industries continue to evolve, the demand for innovative actuator technologies will grow, making these devices even more integral to systems of the future.